CRUSHERS

FEEDING SYSTEM

SCREENING & WASHING

MOBILE SYSTEM

FIXED LAYOUTS

MOBILE PRIMARY IMPACTOR

MOBILE HARD CRUSHING LINE

MOBILE EXTREME HARD CRUSHING LINE

MOBILE VSI CRUSHER

MOBILE CONE CRUSHER

MOBILE SCREENING LINE

MOBILE SCREENING & WASHING LINE

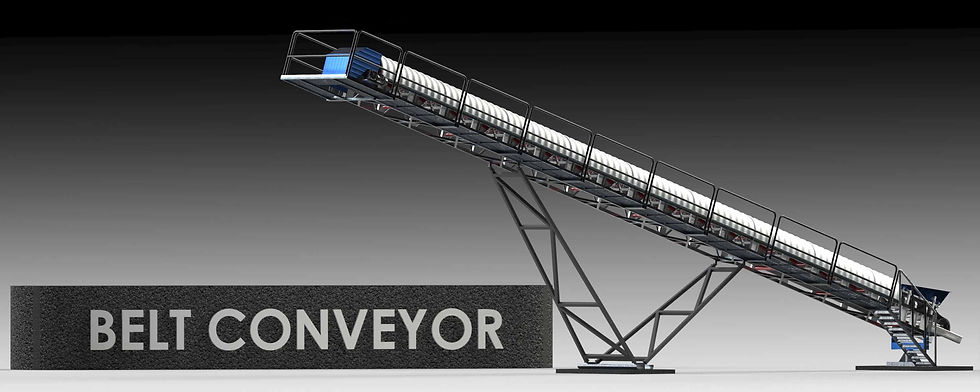

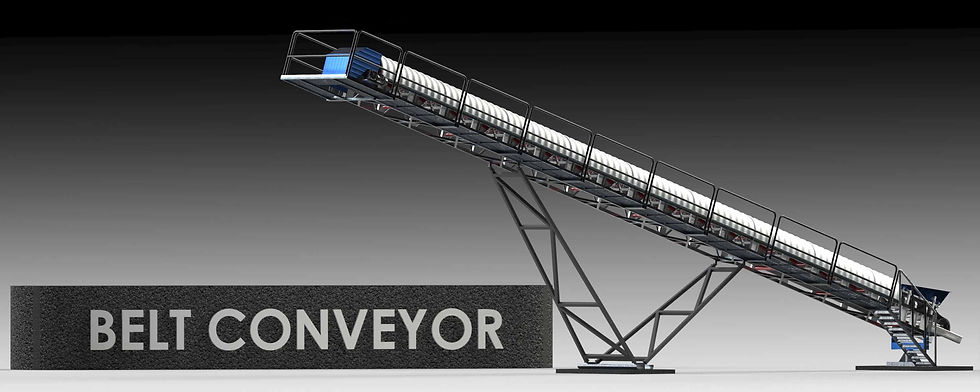

SCB series (BELT CONVEYOR)

A Belt Conveyor is a specialized material handling system designed for transporting crushed stones, aggregates, and other materials within a stone crushing plant or quarry operation. The conveyor is an essential part of the crushing process, providing a continuous and efficient means of moving materials from crushers to screening, washing, or stockpiling areas.

Typically constructed with heavy-duty, abrasion-resistant belts, the belt conveyor is built to withstand the rough and demanding conditions associated with transporting large, heavy, and abrasive materials. The conveyor system features durable pulleys, rollers, and a robust frame that ensures long-term reliability and minimal maintenance.

-- ADVANTAGES --

High Capacity and Efficiency:

-

Designed to handle large volumes of material, facilitating seamless movement throughout the crushing plant.

Durability:

-

Built to endure the harsh conditions of stone crushing environments, with resistant materials and components that can handle heavy and abrasive loads.

Adjustable Speeds:

-

Allows for control over material flow rates, optimizing processing efficiency.

Flexibility:

-

Can be configured for various layouts, including inclined or horizontal transport, to meet the specific needs of a plant.

Reduced Labor Costs:

-

Automates the material handling process, reducing manual labor and increasing overall productivity.